Founded in 1997 and headquartered in Austin, Texas, OriGen Biomedical is a privately-held medical device manufacturer that is experiencing growth. Our company is a leading producer of cryopreservation and cell culture products with a focus on developing a range of solutions to support the treatment of life-threatening diseases such as cancer and genetic conditions. Our products are designed with both the patient and user in mind, and we take pride in our commitment to providing excellent customer service to ensure patient care always remains our top priority. The primary way to achieve this is by attracting and hiring the right people who share our vision.

0

0

0

0

Current Job Openings

How to Apply

Interested candidates should send their resume and salary requirements to origenjobs@origen.com with the subject line as the position(s) you’re applying for.

Unfortunately, due to the volume of candidates, it is not possible to follow up with all applicants, but we invite you to visit OriGen’s Career Page often, as we are updating with new opportunities frequently. We look forward to hearing from you.

Marketing Communications Specialist

POSITION SUMMARY

We are seeking a dynamic and detail-oriented Marketing Communication Specialist to join our team. The Marketing Communications Specialist will be responsible for developing and executing communication strategies to enhance the company’s brand and promote our products. Key responsibilities include creating engaging content for various channels, coordinating marketing campaigns, and analyzing campaign effectiveness. In addition to being an excellent communicator, you should possess strong multitasking and organizational skills.

ESSENTIAL DUTIES AND RESPONSIBILITIES

The essential duties and responsibilities of this position include, but are not limited to the following:

- Write and edit compelling copy for social media, websites, emails, and other marketing collateral.

- Monitor trends in social media behavior that may impact our messaging or tactics.

- Develop messaging around seasonal or timely topics.

- Plan, coordinate, and execute marketing campaigns across multiple channels, including email marketing [quarterly external newsletters] and social media.

- Track, analyze, and report on key performance indicators (KPIs) for marketing campaigns, website analytics, and social media engagement to measure effectiveness and inform future strategy.

- Develop and implement comprehensive marketing communications plans aligned with business goals.

- Conduct market research within the cell therapy industry to assess customer research, market conditions, and competitor data

- Assist in the development of technical marketing content such as white papers, case studies, and blog posts in collaboration with subject matter experts.

- Support public relations activities, including press release writing, media outreach, and award submissions.

- Support marketing campaign planning and execution, including email marketing campaigns, SEO, and PPC campaigns

- Ensure consistent branding and messaging across all internal and external communications.

- Contribute to internal communications initiatives to improve employee awareness of company updates, milestones, and achievements.

- Work with cross-functional teams like sales, engineering, and QA/RA, as well as external agencies, vendors, and designers

COMPETENCIES

- Creative Problem Solving

- Collaborative Working

- Strategic Thinking

- Research Skills

- Analytical Skills

- Results-driven

- Technologically Savvy

- Innovative

- Persuasive

- Self-starting

- Aptitude and motivation to learn new technical information

- Knowledge of sales and marketing processes

- Adaptable to changing priorities

- Motivated and able to motivate others

- Detail Oriented

MINIMUM QUALIFICATIONS (KNOWLEDGE, SKILLS, & ABILITIES)

- Bachelor’s degree in Marketing, Communications, or a related field

- Minimum of 3-5 years’ marketing experience

- Minimum of 1-year Google G Suite: Ability to easily navigate Google Drive, Docs, Slides, Sheets, and Forms programs

- Minimum of 1 year’s experience with an online CRM/Salesforce

- Minimum of 1 year’s experience with social media, digital advertising, and web/email platforms

- Demonstrated ability to use effective and results-oriented problem-solving and critical thinking skills; strong troubleshooting ability

- Strong ability to understand and interpret customer needs; customer-centric; ability to proactively work with diverse work teams (i.e., Sales, Operations, Engineering, Human Resources, Quality)

- Strong interpersonal and people skills

- Strong organization and time management skills with demonstrated ability to meet deadlines

- Exceptional writing, editing, and verbal communication skills

- Ability to work independently and within a team environment on assigned projects from inception to completion

PREFERRED QUALIFICATIONS

- Minimum of 1-year experience in medical device, healthcare, or pharmaceutical marketing experience (or another heavily regulated industry)

- Basic understanding of the WordPress platform or experience editing websites using other platforms and/or content management systems

- Basic skills with graphic design software are a plus: Canva

- Experience with email marketing platforms and/or marketing automation platforms

- Experience with CRM/Salesforce

- Knowledge of SEO best practices, Google Analytics (GA4), and keyword research tools

- Experience writing or editing technical/scientific content for regulated industries

- Experience developing content for internal communications or employee engagement initiatives

- Experience managing external vendors, creative agencies, or freelancers

- Strong presentation design skills (Google Slides, PowerPoint, or Canva)

TRAVEL

<5%

SUPERVISORY RESPONSIBILITY

This position has no supervisory responsibilities; however, the individual may be required to lead projects and ensure participants meet deadlines.

WORK ENVIRONMENT

This is a full-time position. Days and hours of work are typically Monday through Friday, 8:30am to 5pm. In some cases, additional work hours may be required. Must be available to come into our Austin office during normal business hours, Monday – Friday; Option for hybrid schedule once established in role.

This job operates in a professional office environment. This role routinely uses standard office equipment such as computers, phones, photocopiers, filing cabinets, and fax machines.

- Note: OriGen is a fragrance, smoke, smokeless tobacco, and vape-free facility. There is NO use of any tobacco or vape products permitted anywhere on company grounds/property or during any shift, break, or lunch period.

PHYSICAL DEMANDS

The physical demands described here are representative of those that must be met by an employee to successfully perform the essential job duties and responsibilities of this position. Reasonable accommodations may be made to enable individuals with disabilities to perform the functions.

While performing the duties of this position, the employee is regularly required to talk and hear. The employee is frequently required to use hands, fingers, handle or feel objects, tools, or controls. The employee is occasionally required to stand; walk; sit; and reach with hands and arms. The employee must occasionally lift and/or move up to 25 pounds. Specific vision abilities required by this position include close vision, distance vision, color vision, and the ability to adjust focus. The noise level in the work environment is usually moderate.

Salary:

Cleanroom Tech for Medical Device Production - Morning and Evening Shift

Morning Shift: Work hours: five days, 8-hour shifts (Monday-Friday 5:30am – 2:00pm).

Evening Shift: Work hours: four days, 10-hour shifts (Monday-Thursday 2:15pm – 12:45am).

The Clean Room Tech (CRT) is responsible for the assembly, testing, and packaging of medical devices and components. Required to understand and comply with drawings, written procedures, batch records, and must apply these standards to their work.

Essential Duties and Responsibilities

The essential duties and responsibilities of this position include, but are not limited to the following:

- Ability to meet production schedules and deadlines according to quality standards

- Ability to work in a flexible and changing environment

- Ability to follow detailed written and verbal instructions

- Ability to learn multiple tasks and train in other areas as needed

- Ability to work with a variety of tools and equipment

- Ability to maintain all logs, paperwork, and forms accurately

- Required to understand, access, and make entries to documents on the company Electronic Document System

- Ability to accurately perform job duties with minimum supervision

- Ability to adhere to cleanroom dress code and policies

- Ability to work in a multi-cultural team environment and be a team player

- Ability to work in a cleanroom environment for extended periods of time

- Punctual and Reliable!!

Required Skill Sets

- Must be detailed oriented and be able to focus on a repetitive task for long periods of time

- Must be proficient on a computer, possessing basic navigation and program knowledge

- Must be able to absorb, assimilate and accurately recall/locate and retain large quantities of data/information

- Must be able to read, write, speak and fully understand English

Competencies

- Adaptability/Flexibility

- Ethical Conduct/Integrity

- Communication/Listening

- Detail-Oriented

- Interpersonal skills

- Personal Effectiveness

- Teamwork

Minimum Qualifications (Knowledge, Skills, and Abilities)

- Basic computer navigation and program knowledge

- Strong organization and time management skills with the demonstrated ability to meet deadlines

- Pays very close attention to detail

- Ability to work independently and within a team environment

Preferred Qualifications

- Prior Clean Room experience preferred

Compensation

Based on experience and ability

How to Apply

Interested candidates should send their resume, title(s) of job for which they wish to be considered, and salary requirements to origenjobs@origen.com. Unfortunately, due to the volume of candidates, it is not possible to follow up with all applicants, but we invite you to visit OriGen’s Career Page often, as we are updating with new opportunities frequently. We look forward to hearing from you.

Don't See a Position That Applies to You? Get on Our List!

If you are interested in working at OriGen, but do not see a current opening that fits your skillset, please use the form below and you’ll be notified if a similar role becomes available.

Please only click submit once and wait for your entry to go through.

Why Work at OriGen Biomedical

Are you looking for a job that excites and inspires you while making a difference in people’s lives?

Working at OriGen means you are directly making an impact on patients’ lives. Our products play a pivotal role in the treatment of a wide range of conditions and life-threatening diseases, including cancer. Every day, your work will have a meaningful impact on the well-being of individuals around the world. You’ll enjoy a positive, stimulating, and inclusive environment where collaboration and creativity thrive. At OriGen, you’ll find ample opportunities to expand your skills, take on new challenges, and carve out a rewarding career path—all while knowing that your efforts contribute significantly to making a difference in the lives of those we serve.

Our Full-Time Benefits

The physical, mental, and financial health of our employees and their families is a top priority for OriGen. This is why we have a strong, competitive benefits program, which includes:

- Competitive pay with possibilities of bonuses and merit-based raises

- Health, vision, and dental insurance plans available

- Base-level health insurance is free to employees

- Employer-paid long-term disability and life insurance up to 1 year of employee’s annual salary

- 401(k) Retirement Savings Plan with up to 4% matching contribution

- Flexible work schedule for most office staff

- Generous paid time off, including ten company holidays, paternity/maternity leave, and bereavement leave

- Employee Stock Ownership Program (ESOP)

- Home office improvement incentives for remote workers

- Awards and recognition

- Educational Assistance Program for undergraduate, graduate, and post-graduate studies

- Professional development and training opportunities

- Two different schedules for production employees

- 1st shift: M-F 5:30am – 2:00pm

- 2nd shift: M-Th 2:15pm – 12:45am (includes differential pay)

Our Mission

We create innovative medical products which improve people’s lives.

Our Vision

To be the supplier of choice for single-use disposables within cell and gene therapy and to support transformational therapies across the world.

Our Credo

While our primary responsibility is to the patients who ultimately receive our product, our second responsibility is to our staff, the men and women who work for OriGen. We believe each employee should have a sense of security in their job, fair and adequate wages, as well as clean and orderly working conditions. Management must be qualified and just, and the working environment pleasant.

Core Values

- Be an example of Corporate Responsibility

- Demonstrate excellence in all aspects of the company

- Foster incremental innovation

- Provide unparalleled customer service

- Advancement opportunity based on merit

- Our work should benefit the community and the world

What Employees are Saying

via 2024 Energage employee survey

What Makes Working at OriGen Unique

We not only improve the lives of our customers and their patients, but we also try to improve the lives of our own employees by fostering good company culture. OriGen offers a friendly workplace where individuals treat each other with respect and kindness. Meaningful interactions between colleagues are encouraged. We are always looking to nurture talent and provide opportunities to progress, which is why we often fill available roles from within.

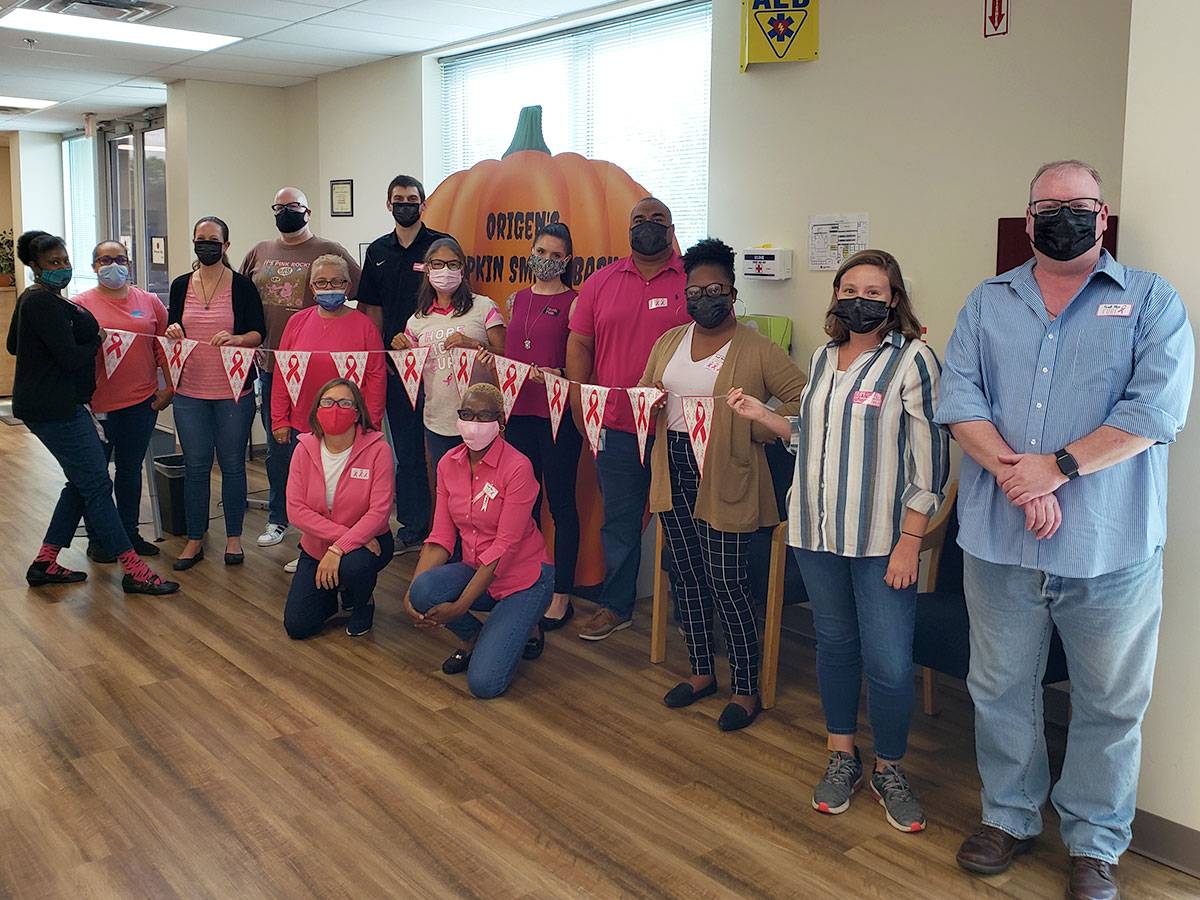

OriGen is committed to creating a workplace where everyone feels valued, included, and engaged. Our employee-led group, The VIBE (Value, Inclusion, Belonging, and Engagement), organizes fun in-office activities that bring our team together and strengthen our company culture.

We are a woman-led business and strive to provide an inclusive workplace for all employees, no matter their ability, age, background, color, culture, gender identity, language, orientation, religion, size, or veteran status.

Workplace Expectations and Policies

At OriGen Biomedical, ensuring a clean and safe environment is a top priority. Our cleanroom facilities and overall workplace adhere to high hygiene standards to protect both our employees and the life-saving products we manufacture.

- Personal Hygiene: Employees are expected to maintain high standards of personal cleanliness, and those with any illnesses or conditions that could compromise product safety are managed promptly. To ensure a contaminant-free environment, we uphold a fragrance-free and tobacco-free policy.

- Cleanroom Practices: Employees must wear gloves in cleanrooms, avoid face contact, and adhere to our sanitation protocols.

- Health Precautions: Employees with symptoms of illness, such as coughing, sneezing, or other contagious conditions, must report to their supervisor for reassignment or leave if necessary.

- Dress Code & Culture: We value professionalism, and employees follow our Austin Business Casual dress code for our office employees and provide scrubs, headwear, masks, and gloves for our production employees. Wednesdays are “OriGen Shirt” days, and we celebrate team achievements with quarterly events and an end-of-year party. Employees working in the warehouse are required to wear closed-toed shoes.

OriGen Biomedical is committed to providing a safe, welcoming, and clean environment for all employees, ensuring both personal and product safety.